Metal Drilling Techniques: Stop Work Hardening Now

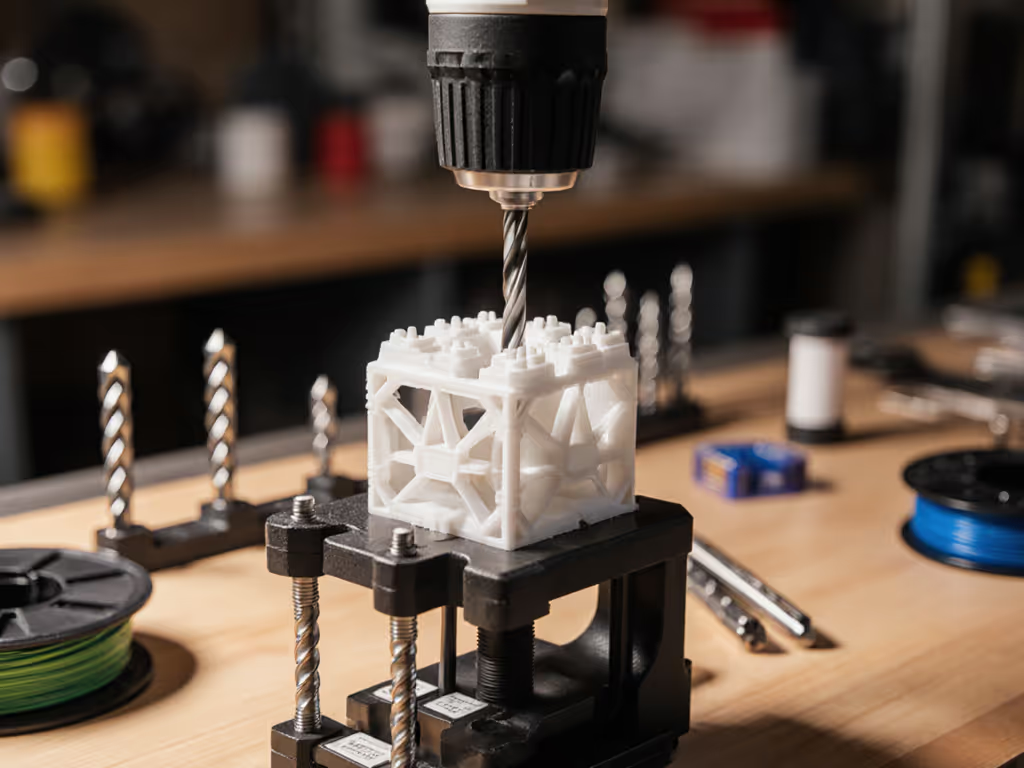

When metal fabrication drill techniques go wrong, you're not just fighting a stubborn material (you're burning productivity and reputation). Work hardening turns soft metals brittle mid-drill, stalls bits in stainless steel, and drags down crew timelines. Yet most guides focus only on the bit-to-metal interface, ignoring the workflow context that determines whether your battery platform supports or sabotages the operation. Let's fix that.

Why Work Hardening Kills Your Timeline

Work hardening occurs when metal molecules compress and deform during drilling, creating localized heat and resistance. This isn't just a physics problem, it's a workflow crisis. Aluminum drilling experts know soft metals like aluminum and brass resist heat dissipation. When you drill too fast without lubrication, the bit creates the very hardness that stalls it. Stainless steel? That chromium layer fights back aggressively. You'll feel the drill bog down, hear the RPM drop, and watch productivity evaporate (often right when your battery hits critical charge).

uptime beats peak specs when drilling hardened zones. A 1,200 in-lb torque rating means nothing if thermal throttling cuts output mid-hole.

Material-Specific Tactics (That Respect Your Battery Budget)

Aluminum: Keep It Cool or Pay in Downtime

Aluminum grabs bits and heats fast. During a school retrofit I ran, crews using standard HSS bits on aluminum framing lost 8 hours weekly swapping bits and rebooting dead batteries. We switched to carbide-tipped drills with parabolic flutes (better chip extraction = less heat) and mandated coolant use. The drill bit for drilling aluminum needs shallow angles to slice, not plow, reducing amperage spikes that drain batteries. For bit geometry, lubrication, and workholding essentials across materials, see our power drill accessories guide.

Workflow adjustment: Run at 60% max RPM for 1/4" aluminum. Pair with a fast-charging battery platform that recovers during coolant breaks. Checklist:

- Use high-speed steel (HSS) or carbide-tipped bits

- Apply light, consistent pressure (over-pressing triggers work hardening)

- Lubricate with cutting oil or WD-40

- Pause every 1/2" depth to clear chips

Stainless Steel: Don't Let the Chromium Layer Win

Stainless steel's corrosion resistance comes from its chromium layer (which hardens instantly under friction). That drill bit for drilling stainless steel must be cobalt or titanium-coated. Standard HSS bits dull in seconds. But here's the crew-killer: most drills ramp up speed too fast for this material. You need low RPM (200-400) with high torque to push through the hardening layer without sparking. A brushless drill comparison explains how brushless motors deliver better low-RPM torque and cooler operation for stainless.

Pro tip: Make a 1/16" pilot hole first with a center punch. This prevents bit walking that wastes battery cycles on repositioning. One HVAC crew cut stainless ductwork time by 35% after standardizing on variable-speed drills with torque control, no more overdriving bits that then stall.

Sheet Metal Work: Precision Over Power

Thin sheet metal (<1/8") requires technique, not brute force. Too much pressure = buckling. Too little = chatter = work hardening. For sheet metal work, use a stepped or conical drill bit metal fabricators trust. Start slow (300 RPM), then gently increase speed. For alignment tips without a drill press, follow our drill straight holes guide. Clamp material firmly between wood backer boards (a technique that prevents vibration-induced hardening and extends battery life by reducing erratic load spikes).

Critical insight: Cordless drill runtime plummets when drilling thin metal because intermittent loads trick the battery management system. Bring 50% more batteries than you'd calculate for wood.

Your Battery Platform: The Hidden Variable in Metal Drilling

During a school retrofit project, we replaced three competing battery systems with one standardized platform. The pivot wasn't about torque ratings, it was recognizing that mixed brands created dead-tool moments whenever crews hit hardened zones. Standardizing on fast-charging batteries and colocating chargers with drill stations cut mid-day dead-tool shuffles by 90%. One battery cart replaced three. Plan packs and chargers with our cordless battery kits guide to stop runtime guesswork. That weekly tally of eight fewer lost hours transformed how I view battery planning.

Batteries are a workflow, not accessories (plan them like materials).

For metal drilling specifically:

- Tool selection matters less than ecosystem consistency. That Makita hammer drill (XPH14Z) performs well on stainless with its 0-2,100 RPM range, but only if your chargers match the workflow. A Milwaukee drill (2804-20) with RedLithium XC5.0 packs delivers longer runtime in stop-start metal drilling, but only if your crew doesn't waste time hunting batteries across incompatible platforms.

- Charge strategically around coolant pauses. While bits cool, swap batteries. A 30-minute fast charger at the workstation beats an extra battery you can't recharge mid-shift.

- Track depth, not just holes. Work hardening increases with depth. Drill 10 holes at 1/2" depth, and you'll drain batteries faster than 10 holes at 1/4" depth (even with identical bits). Map this in your rotation schedule.

Makita XPH14Z 18V LXT Brushless Hammer Drill

The Workflow-First Drilling Checklist

Before you mark your first center punch, answer these timeline-aware questions:

- What's the hardness profile? Soft aluminum hardens differently than stainless steel. Adjust RPM expectations accordingly.

- Hard metals: ≤400 RPM

- Soft metals: ≤1,000 RPM

- Stainless: ≤600 RPM with pilot hole

-

How will chip evacuation affect battery cycles? Parabolic flutes reduce clogging (and heat spikes) but require specific RPM ranges. Stay within them.

-

Where are your coolant breaks? Schedule battery swaps during these pauses. No more dead drills mid-sequence.

-

Is your battery platform scaled for metal? One crew working thin sheet needs different capacity than a team drilling 1/2" steel plates. Standardize packs by job type.

-

Can you deburr without swapping tools? Use a slightly larger drill bit by hand for quick deburring, preserving battery charge for primary tasks.

Stop Fixing Symptoms, Start Fixing Workflow

Work hardening isn't just a metal problem, it's a planning failure. When your drill stalls mid-hole, you're losing more than that one penetration. You're burning schedule buffers, risking thermal damage to the tool, and creating frustration that compounds across the crew.

The solution isn't a fancier bit. It's recognizing that batteries are logistics. Treat your drilling platform like an operations decision, not a one-off purchase. Map RPM requirements to battery discharge curves. Position chargers where coolant breaks happen. Standardize across crews so no one waits for the 'stainless steel battery'.

Uptime beats peak specs every time. Plan your battery ecosystem like you plan your materials list, and watch dead-tool moments evaporate.

Further Exploration: Download our free Metal Drilling Workflow Calculator (includes RPM/battery runtime correlations for common metals). Or join Tuesday's live Q&A on managing battery heat during sustained metal drilling operations.